In today ’s fast-paced world, technology is changing everything, including how we manufacture products. Robotics has become a game-changer in the manufacturing industry, helping businesses create goods faster, more efficiently, and with greater precision. From car assembly lines to packaging food products, robots are now an essential part of modern factories.

This article explains how robots are used in manufacturing, the benefits they bring. and the challenges companies face when adopting them.

Robotics in Manufacturing

Using robots in manufacturing is n’t new. It started in the 1960s, but the technology has come a long way since then. Modern robots are smarter, faster , and more versatile. They use advanced technology like artificial intelligence (AI) and sensors to perform tasks that were once too complicated for machines.

Today, robots are not just about replacing humans; they are working alongside them to create a better, more efficient way of making things.

Why Robots Are Transforming Manufacturing?

1. Faster Production

Robots don ’t need breaks or rest. They can work 24/7, performing repetitive tasks much faster than humans. This helps manufacturers meet high demands and reduce production time.

2. High Precision

In industries like electronics or healthcare, even the smallest mistake can be costly, Robots are incredibly precise, which makes them perfect for delicate tasks like assembling tiny components or measuring exact amounts.

3. Safer Workplaces

Manufacturing can be dangerous, with tasks involving heavy lifting, toxic chemicals, or extreme temperatures. Robots take on these risky jobs, keeping human workers out of harm’s way.

4. Saving Costs Over Time

While buying and setting up robots can be expensive initially, they save money in the long run by reducing errors, improving efficiency, and lowering labor costs.

5. Flexibility for Different Tasks

Modern robots can be reprogrammed to handle various jobs, making it easier for manufacturers to adapt to changes, like switching production from one product to another.

Where Are Robots Used in Manufacturing?

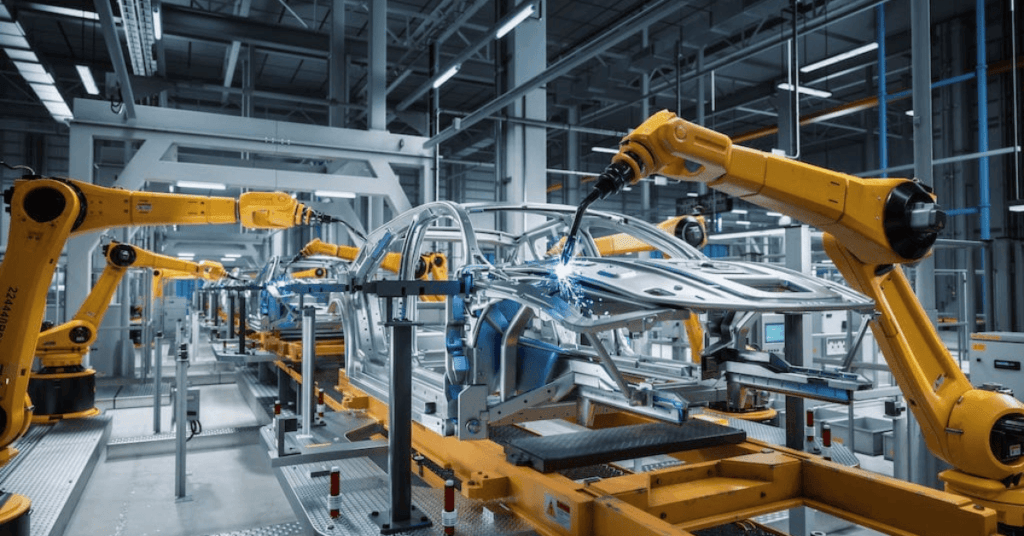

1. Assembly and Welding

Robots are widely used in assembling and welding parts. They are especially helpful in industries like automotive and aerospace, where precision and strength are crucial.

2. Moving Materials

Robots can transport heavy materials, organize inventory , and load items onto machines, speeding up workflows and reducing physical strain on workers.

3. Checking Quality

Robots with cameras and sensors can inspect products for defects, ensuring every item meets quality standards. This is especially important in industries like food production and electronics.

4. Packaging and Shipping

Robots make packaging and palletizing faster and more accurate, helping businesses prepare products for shipping efficiently.

5. 3D Printing

In modern manufacturing, robots also assist in 3D printing , creating complex designs and customized products with ease.

Challenges of Using Robots in Manufacturing

While robots bring many benefits, there are challenges too;

- High Upfront Costs: Setting up robots requires a significant investment in equipment, software , and training.

- Training Workers: Employees need to learn how to use and maintain robots, which can take time and resources.

- Integrating with Existing Systems: Adding robots to current workflows can be complicated and might disrupt production temporarily.

- Cybersecurity Risks: As robots connect to networks, they become vulnerable to cyberattacks, requiring strong security measures.

Future of Robots in Manufacturing

The role of robots in manufacturing is only going to grow. Collaborative robots , or “cobots,” are becoming more popular because they can work safely alongside humans. Autonomous robots, which move around factories independently, are also becoming more common.

Advances in AI and machine learning will make robots even smarter, allowing them to adapt to changes and learn new tasks quickly. As the cost of robotic technology decreases, smaller businesses will also be able to take advantage of these tools, making automation accessible to everyone.

Robotics is changing manufacturing for the better. Robots make production faster, safer. and more precise, helping companies stay competitive in a demanding market. While there are challenges to overcome, the benefits of using robots far outweigh the difficulties.

As technology advances, the partnership between humans and robots will continue to grow, opening up new possibilities in manufacturing. Whether it’s assembling cars, packaging goods, or creating custom designs, robots are leading the way into a smarter, more efficient future.

Frequently Asked Questions(FAQs)

What is robotics in manufacturing?

Robotics in manufacturing refers to the use of robots to automate various tasks in factories, such as assembly, material handling, quality control, and packaging. These robots improve efficiency, precision, and safety in production processes.

What are the main benefits of using robots in manufacturing?

Robots offer several advantages, including:

Faster production and reduced downtime.

High precision for tasks requiring accuracy.

Safer work environments by handling dangerous tasks.

Long-term cost savings by reducing errors and labor costs.

Flexibility to adapt to different tasks and production needs.Where are robots commonly used in manufacturing?

Robots are used in various manufacturing areas, including:

Assembly and Welding: For putting together or joining parts.

Material Handling: To move heavy items and organize inventory.

Quality Control: To inspect products for defects.

Packaging and Shipping: To prepare goods for delivery.

3D Printing: For creating customized and complex designs.What challenges do manufacturers face when adopting robots?

Key challenges include:

High upfront costs for installation and training.

The need to train workers to operate and maintain robots.

Difficulties in integrating robots into existing systems.

Cybersecurity risks due to network connectivity.What does the future hold for robotics in manufacturing?

The future of robotics in manufacturing includes smarter and more adaptable robots powered by artificial intelligence. Collaborative robots, autonomous mobile robots, and advances in machine learning will make manufacturing even more efficient, scalable, and innovative.